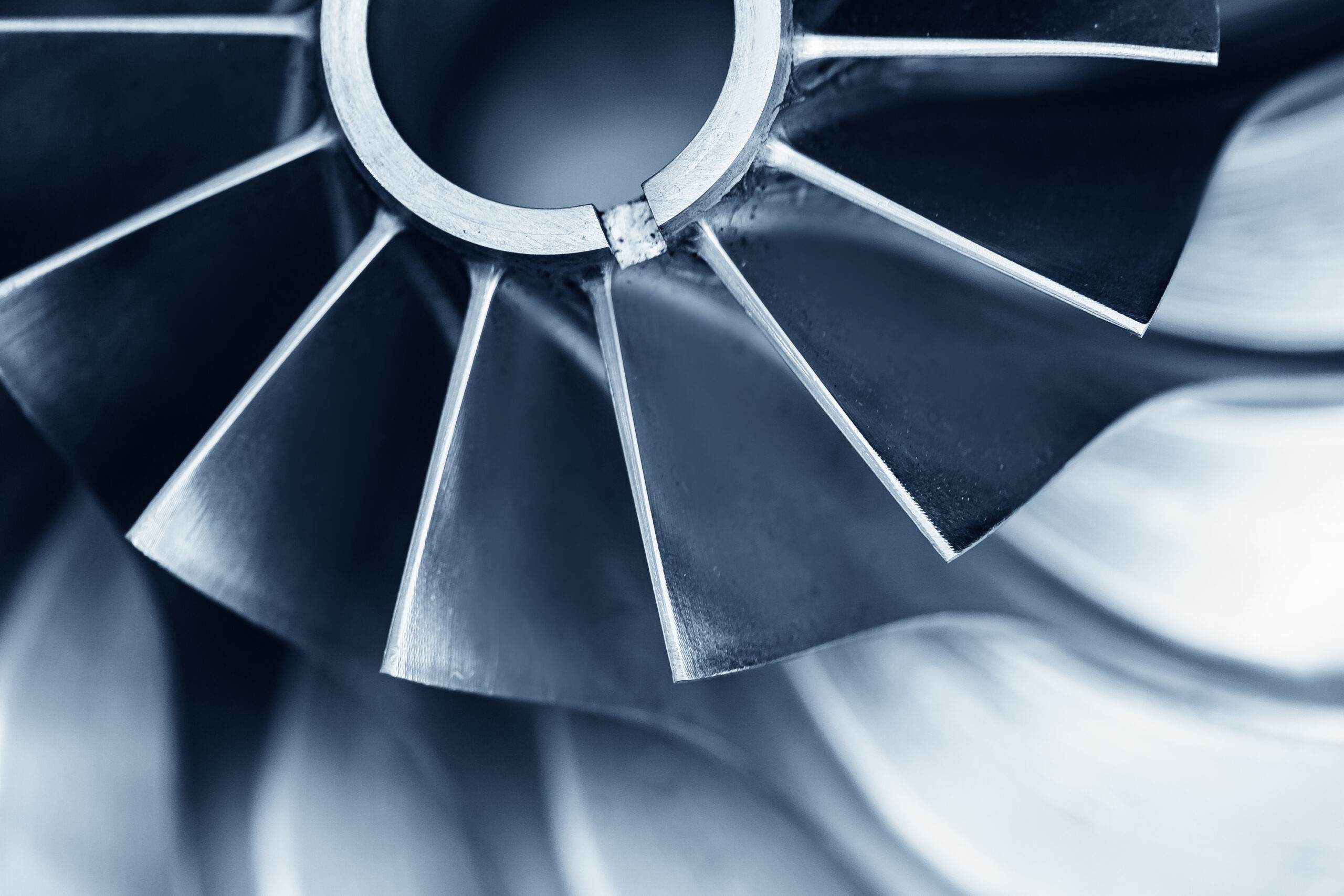

Oasis Series®

Our Oasis Series Systems

What makes the OASIS® Series revolutionary?

The Oasis Series® Systems offered by AQUASGROUP are considered revolutionary because of their unique and innovative design. These systems have several key features that set them apart from the competition. Some of the key factors that make the Oasis Series® Systems revolutionary include:

Zero Liquid Discharge: The Oasis Series® Systems are designed to require no drain. Leveraging our expertise in the applications engineering of Best Available Technologies, rinse water is continuously re-purified at high-recirculation rates resulting in high quality, consistent rinsing while eliminating chemical carryover and resulting cross contamination. This directly relates to enhanced process quality while reducing operating costs and minimizing waste generation.

Customization and Process Optimization: The Oasis Series® Systems are fully customizable and are designed to be optimized for a given process, resulting in enhanced product quality and low lifecycle costs.

Energy efficiency: The Oasis Series® Systems are turnkey systems, designed to be energy-efficient by matching the size of the system to the required work envelope, minimizing heating and ventilation requirements which helps to reduce energy consumption.

Enhanced Process Control: The latest in controls technologies coupled with our extensive programming and automation experience results in process optimization supported by user-friendly interfaces and easy-to-read displays which make it easy for engineers to configure and operators to manage the process. Additionally, flexible communication protocols allow centralized data management systems to collect and analyze critical process information.

Durability and longevity: We utilize industrial hardened materials and components to deliver durable and long-lasting systems, minimizing downtime and maximizing the value of your investment.

Real-time Data Acquisition: The Oasis Series® Systems are equipped with advanced sensors and monitoring systems that provide real-time process data such as process time, temperature, pH, conductivity, system performance, and other key metrics, resulting in a certified, repeatable process and allowing operators to make informed decisions to optimize the performance of the system and process.

State of the Art Automated Material Handling: The Oasis Series® Systems can include state-of-the-art automated dynamic material handling technology, which ensures efficient and precise handling of materials throughout the manufacturing process, maximizes efficiency and reduces operator exposure.

Comprehensive Service Agreements: AQUASGROUP offers comprehensive service agreements that include regular maintenance, repair and service of the systems, ensuring smooth and efficient operation of the systems over the long term.

| Applications |

|---|

| Immersion Parts Washers |

| Spray Parts Washers |

| Power Wash Booths |

| Metal Finishing Systems |

| Precision Cleaning |

| Electroplating |

| Electropolishing |

| Anodizing |

| Etching |

| Conversion Coating |

| Passivation |

| Non-Destructive Testing (NDT) |

| Fluorescent Penetrant Inspection (FPI) |

| Features |

|---|

| Manual or automated material handling |

| Integrated controls and programming |

| Real-time process monitoring and data acquisition |

| Industry 4.0 compliant |

| Zero Liquid Discharge Designs |

| Minimized chemical cross contamination |

| Additional Services |

|---|

| Installation |

| Training |

| Preventative Maintenance Service |

| Calibrations |

| After Sale Support |

| Available Technologies |

|---|

| Dynamic Automation |

| Instrumentation (temperature, conductivity, density, refractance, pH, ORP, RTD) |

| Water Recycling |

OASIS® Series Systems require no drain.

In each design category, process rinse water is continuously re-purified for continuous re-use using integrated Best Available Technology. Consistently pure rinse water naturally protects all process chemistry from cross contamination directly offsetting costs through enhanced quality and waste minimization.

Furthermore, hot, deionized water is an effective solvent for the removal of water-soluble contaminants. Why use a detergent to remove water soluble contaminants?

The bottom line.

OASIS® Series Systems save money through process bath optimization, waste minimization and process rinse water consistency.

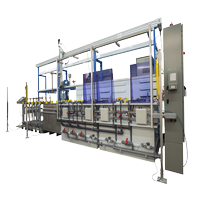

Cellular Closed Loop Continuous Metal Strip Washer

AG OASIS® SERIES CSW-CELL Cellular Continuous Metal Strip Washer with integrated ZLD+ Technology.

Manual Closed Loop Spray Parts Washer

AG OASIS® Everinse STS Manual Closed Loop Spray Parts Washer

Cellular ZLD Parts Washer

AG OASIS® SERIES EW/2424-M Manual ZLD+ Parts Wash / Rinse Module for the removal of mineral oil based contaminants.

Side Arm Automatic Electropolishing Line

AG OASIS® SERIES MF-EP/A Side Arm Automatic ZLD+ Electropolishing Line

ZLD+ Manual Passivation Line

AG OASIS® SERIES MF-P/M for citric or nitric acid passivation processes including integrated recycled process rinse water for zero liquid discharge.

Closed Loop Cellular Parts Washer

AG OASIS® SERIES ER/1818-M Cellular Parts Wash / EveRinse Module for removal of water soluble contaminants on nonferrous substrates.

ZLD+ Precision Stainless Steel Tube Washing Module

AG OASIS® EW-ES ZLD+ STAINLESS STEEL TUBE WASHER

Manual Spray Rinse Module

AG OASIS® Everinse STS Spray Rinse Module

Engineering

Nicholas Paolo, Jr.

President / Engineering

Mailing Address:

Corporate Headquarters & Fabrication Division

41 Commercial Way

East Providence, RI 02914

Water Technologies & Service Division

830 Waterman Avenue

East Providence, RI 02914